Solder paste is a mixture of granulated alloy powder and flux. These powders include alloys commonly used within solder wire and bars such as tin/lead, tin/silver and pure tin. The end product is a smooth paste with a consistency similar to thick grease. Compared to solder wire, solder paste is a turnkey product since it contains enough flux mixed into the paste to ensure sufficient wetting. Further, the consistency of solder paste enables very precise application whether achieved via automatic dispensing or stenciling, giving reliable solder joints. When choosing the right solder paste, users need to consider the same criteria as when selecting a solder wire. Table 1 below summarizes the solder paste options available at MG Chemicals.

|

|

|||

|

Flux Classification |

REL0 |

ROL0 |

ROM1 |

|

Flux Activity |

Low |

Low |

Moderate |

|

Corrosive |

No |

No |

Mild |

|

No Clean Flux |

Yes |

Yes |

Yes |

|

Melting Temperature (°C) |

183 |

221 |

138 |

Table 1: Comparison of MG Chemicals Solder Pastes

Silver Solder Paste

Due to health concerns of leaded products including solder, lead-free options are available such as SAC305 which is an alloy of tin, silver and copper. Compared to leaded options, silver solder has superior electrical and thermal conductivity making them a suitable choice within high amperage devices.

Solder Paste vs. Flux

It is important to differentiate between solder paste and flux. Flux is a cleaning agent that removes surfaces oxides thus lowering surface energy which enables solder to wet out and better adhere to surfaces. Common fluxes include pine tar rosin, synthetic resins or organic acids. Comparatively, solder paste is a mixture of flux with alloy powder making its application a one-step process.

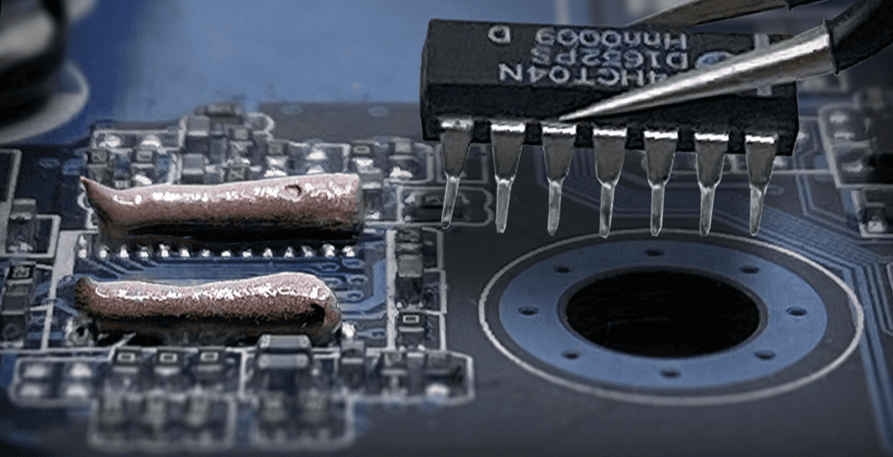

Application Techniques: Applying with a Solder Paste Stencil

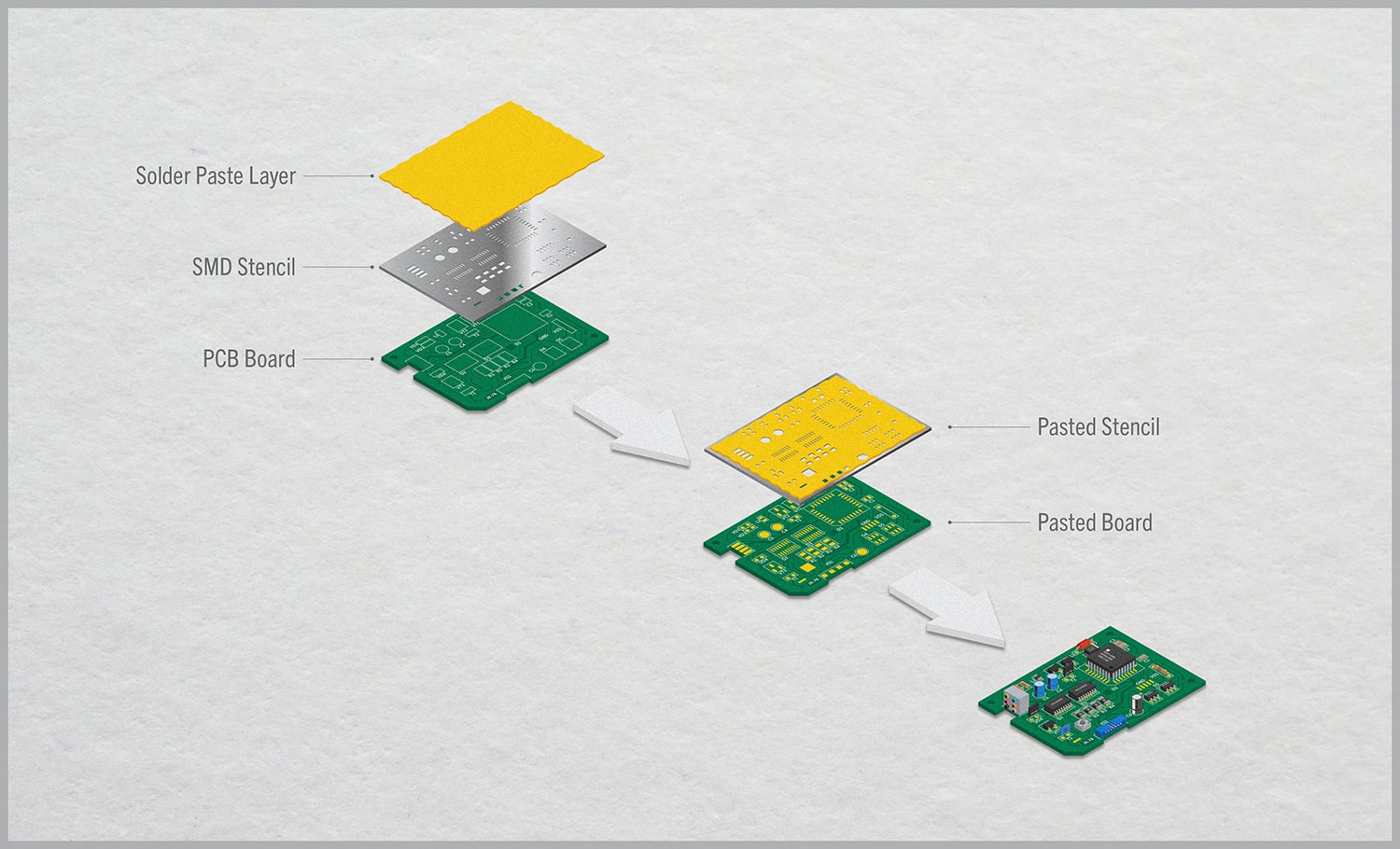

Another big advantage of solder paste is its utility for bonding surface mount devices (SMDs). With solder wire, bonding SMDs can be a timely and cumbersome process; however, with solder paste, users can apply custom stencils over the circuit board and quickly apply solder paste to multiple target areas. The SMDs can then be quickly soldered onto the board via a reflow process which improves throughput and reduces errors. Figure 1 below shows a schematic of solder paste being applied through a stencil.

MG Chemicals compliments its solder paste with a full range of solder products including wire, flux, desoldering braid, tip tinner, flux remover and solder mask. Please see our video which reviews some of our product offerings and how to use them.