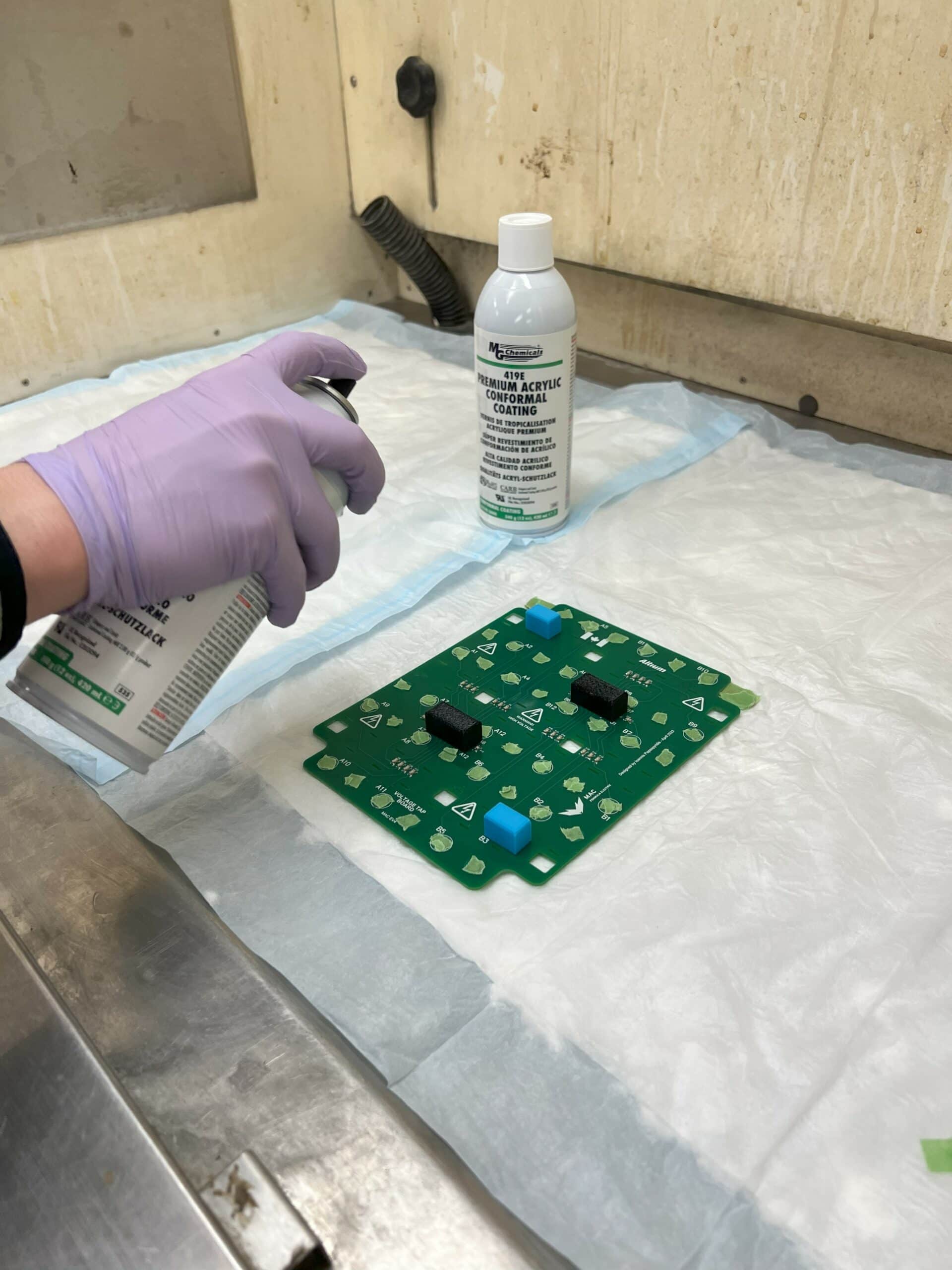

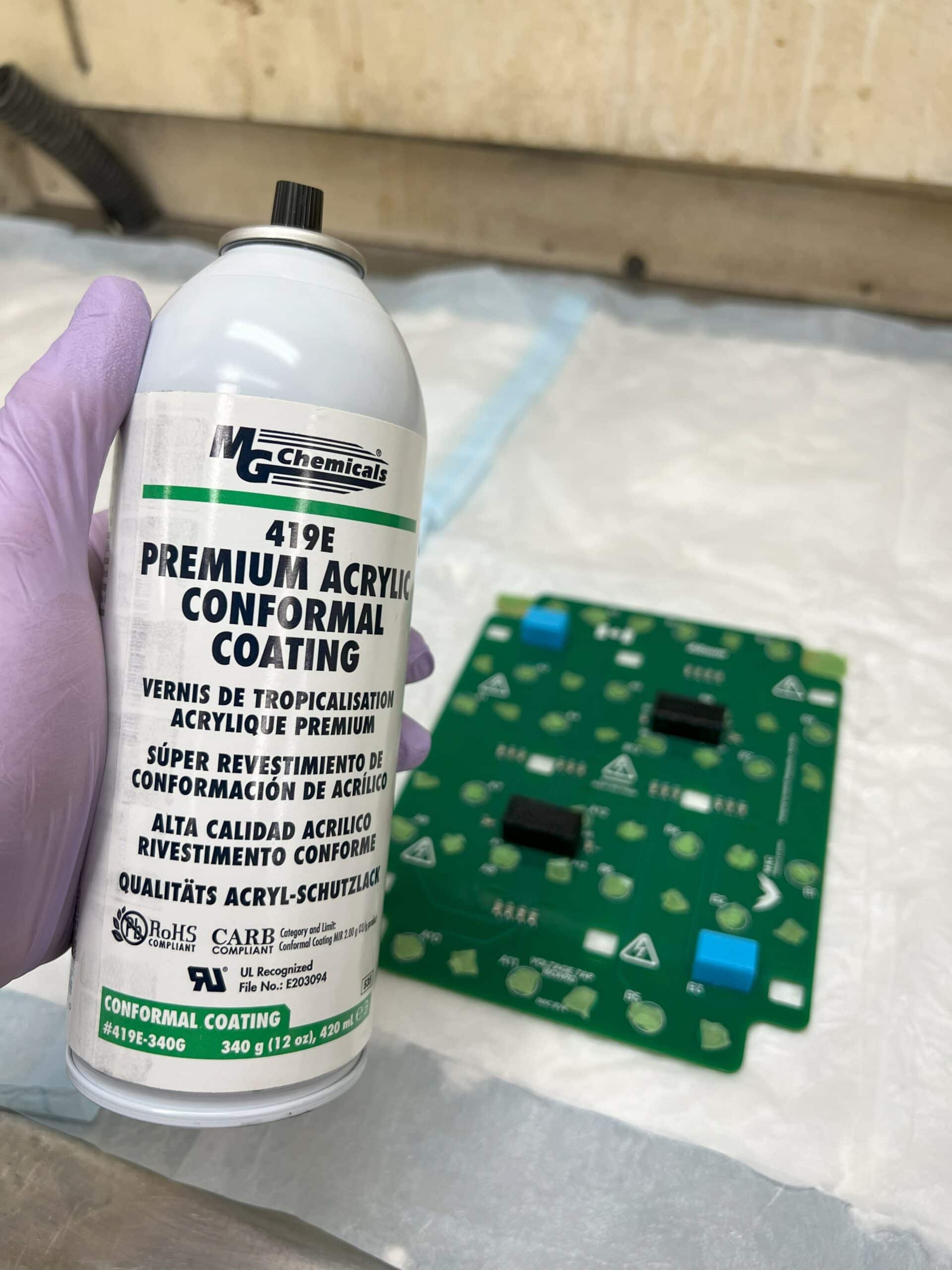

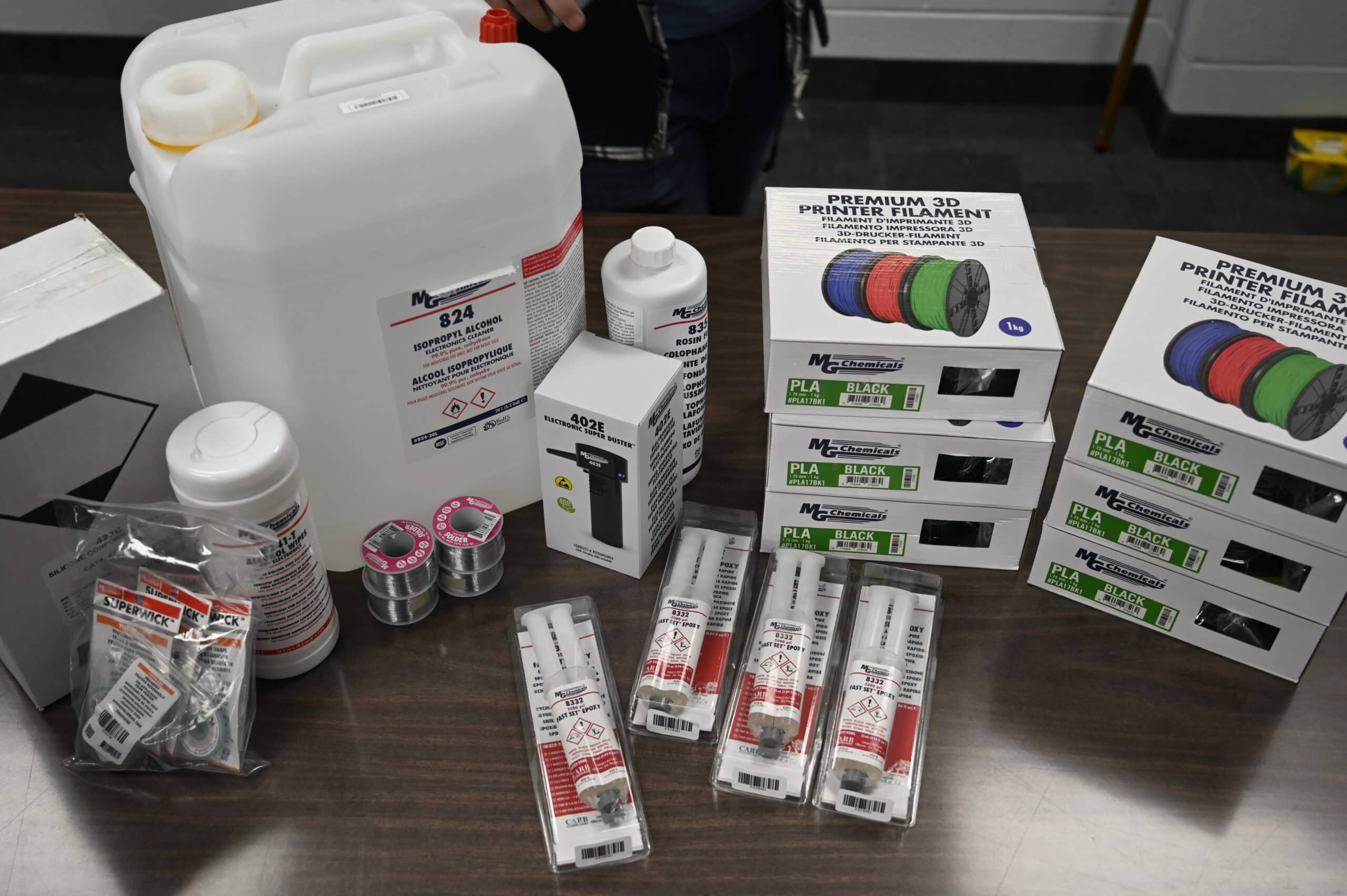

At MG Chemicals, we’re committed to driving innovation and empowering the next generation of scientific pioneers. Our University Project Sponsorship opportunities are tailored to fuel creativity, collaboration, and groundbreaking discoveries within the academic sphere. By aligning with universities and passionate students, we strive to cultivate an environment that fosters ingenuity and real-world problem solving. If you’re a university educator, researcher, or student looking to transcend the boundaries of chemistry and technology, we invite you to explore the endless possibilities with MG Chemicals.

Fill out an application and be a part of the revolution that’s shaping our future!

Apply Now!

A PDF version of the form can be downloaded here