![]()

MG Chemicals has written extensively on thermal management and the different materials available that help prevent modern circuitry from overheating such as adhesives, greases, and gap fillers. We have extended this discussion to the use of thermal interface materials (TIMs) in various industries such as lighting, EV batteries and automotive systems along with a more in-depth technical analysis of materials such as our whitepaper on gap fillers. This paper discusses our newest TIM products, silicone-free thermal gels.

Issues with Silicone TIMs

Traditionally, silicone-based gap fillers have been a popular TIM because of their wide temperature range, high thermal conductivity, and low modulus. The volatility of silicone, however, does present challenges to circuit designers as these materials can become volatile under high temperatures or compression. This volatility can result in outgassing and subsequent migration across components or onto optical lenses which can negatively impact system performance. This becomes particularly critical in safety systems like advanced driver assistance systems (ADAS) where even a small delay in signal transmission can cause malfunction.

Thermal Gel

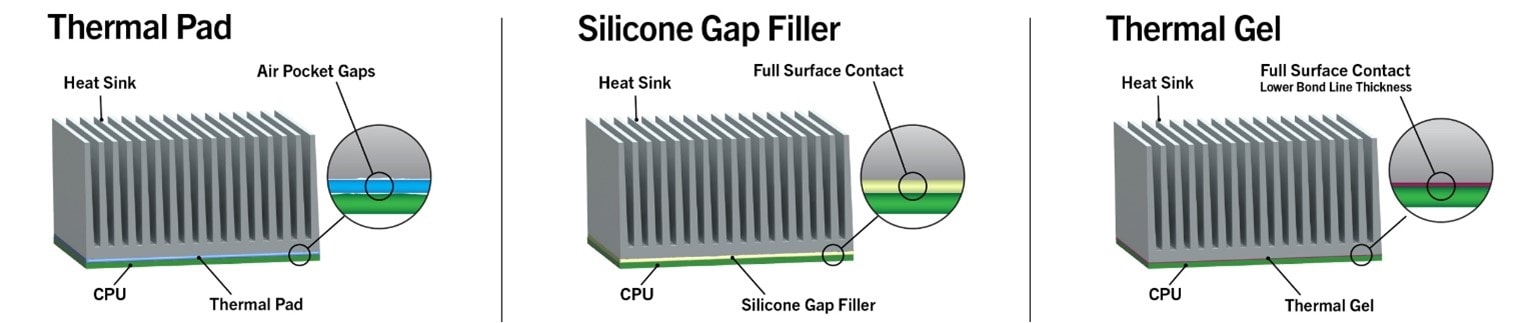

MG Chemicals’ thermally conductive gels are an alternative to more traditional TIMs such as silicone gap fillers and thermal pads. These one-component gels have exceptional thermal conductivity and due to their low modulus can be compressed down to very low bond line thicknesses to offer low thermal impedance. Figure 1 below demonstrates the advantage of thermal gels over other TIMs materials.

Figure 1: Visual comparison of different TIMs including thermal pad, silicone gap filler and thermal gel

The viscosity is ideal for form-in-place applications and because these materials do not cure, devices can be powered up immediately after application. Table 1 below compares our three new thermal gels to more traditional TIMs such as silicone gap fillers and thermal pads.

|

|

Silicone Gap Filler |

Thermal Pad |

|||

|

Thermal Conductivity (W/m·K) |

3.5 |

5.1 |

6 |

2-4 |

1-20 |

|

Flame Retardant |

Yes |

Yes |

Yes |

Yes |

Yes |

|

Components |

1 |

1 |

1 |

2 |

1 |

|

Conformal |

Yes |

Yes |

Yes |

Yes |

No |

|

Temperature Range (°C) |

-55 to 120 |

-55 to 150 |

-55 to 120 |

-60 to 150 |

-60 to 180 |

|

Immediate Use |

Yes |

Yes |

Yes |

No |

Yes |

Table 1: Comparison of MG Chemicals thermal gels to traditional TIMs

MG Chemicals’ thermally conductive gels provide a silicone-free solution to the thermal management issues brought on by miniaturization and data growth. These products feature exceptional thermal conductivity, flame resistance, low thermal impedance, and immediate operational readiness.