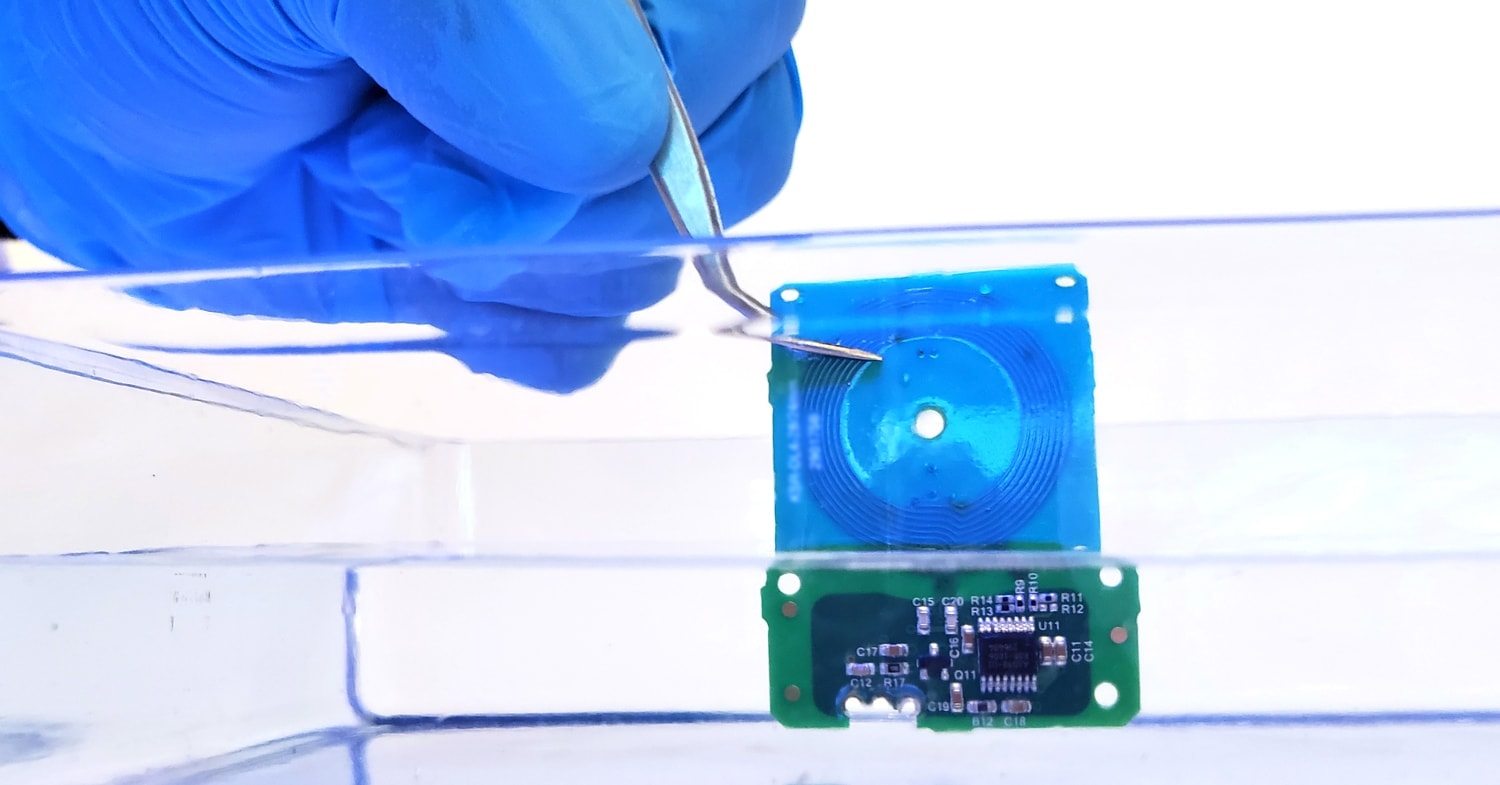

How do I remove conformal coatings from PCBs?

It depends on the coating’s chemistry. For thermoplastic materials such as acrylics or silicone coatings, the cured film can easily be removed with common solvents like acetone or n-butyl acetate. For more durable thermoset coatings such as polyurethane, epoxy and UV cure, use a more aggressive stripper like MG’s 8309 liquid or 8310A gel. The table below summarizes most effective methods for removing coatings of different chemistries.

| Material | Method |

| Acrylics | Easily removed using common solvents like Ketones (e.g., acetone) or esters. |

| Polyurethanes | Can be removed using 8309 or 8310A stripper. Takes 5-10 minutes. |

| Silicones | Easily removed using common solvents like acetone or esters. |

| Epoxy | Remove using 8309 or 8310A stripper. May take up to 2 hours. |

| UV Cure | Remove using 8309 or 8310A stripper. May take several hours. |

| Parylene | Must be removed with micro-abrasion. Very difficult. |

| Ultra-Thin | Easily removed using common solvents like Ketones |

| Styrenated Block co-polymer | Easily removed using common solvents like Ketones |